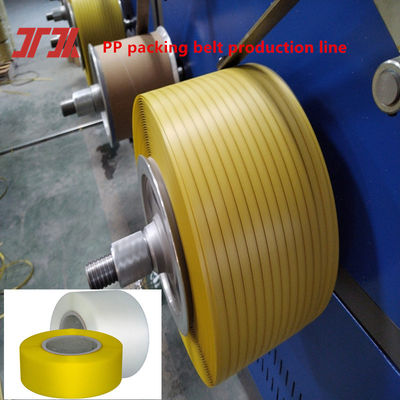

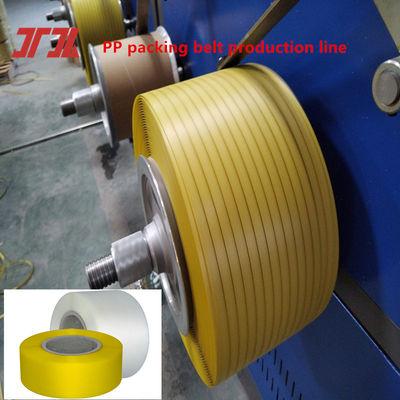

100% Polypropylene PP Strap Manufacturing Machine Single/Twin Screw PP/PET Strap Production Line

DESCRIPTION OF PP STRAP MANUFACTURING MACHINE

pp strap manufacturing machine

1. Raw materials------PP strapping equipment can produce plastic raw materials: recycled materials or new materials to produce strapping;

2. Screw------The equipment adopts high-precision high-quality screws, adopts well-known brands, and has unique parameter design. It has the advantages of large extrusion volume, good plasticization, high hardness and wear resistance; equipped with a quantitative extrusion system, the width and thickness of the produced belts are the same, the error range is small, and it meets the national strapping acceptance standards;

3. Mold-----Foreign CNC machine cutting, high-precision die parts, so that the product molding quality is stable, the width and thickness error range is less than the national strapping acceptance range;

4. Screen changer-----Equipped with a non-stop automatic screen changer, the screen change does not need to stop, and the efficiency is maximized. The 4-net circulation filter has a large area and does not require frequent screen change.

Raw materials ---

100% virgin or recycled polypropylene

PP strapping equipment parameters

| Model |

PP-2 |

PP-4 |

PP-6 |

PP-8 |

PP-10 |

PP-12 |

| Raw material |

PP polypropylene new material/recycled material |

| Number of tapes |

2 |

4 |

6 |

8 |

10 |

12 |

| Width(mm) |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

| Thickness(mm) |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

| Line speed(m/min) |

≧260-300 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

110 |

125 |

135 |

135 |

135 |

| Reducer model |

200 |

220 |

250 |

280 |

280 |

280 |

| Drying barrel (kg) |

100 |

150 |

200 |

200 |

200 |

200 |

| Winding machine |

Automatic winding machine /Semi-automatic winding machine |

| Screen Changer |

Automatic/Manua |

| Production capacity 24H |

2.5-3T |

6-7T |

8-9T |

10-11T |

12-13T |

13--14T |

Machine Highlights:

Automatic addition of calcium carbonate powder reduces costs

PLC control system, capable of storing production data for 99 specifications

Energy-saving and environmentally friendly, high output, low power consumption

Stable operation, low failure rate

PP strap making machine----ADVANTAGES

Easy to operate----The semi-automatic winding machine is simple in design and easy to operate. Workers can learn quickly without extensive training.

Small investment---PP strap making machine is energy-saving and environmentally friendly. It can be produced using PP polypropylene recycled materials and has low manufacturing costs.

Advanced technology-----PP strap making machine has advanced technology and uses high-precision accessories. The PP BELT produced is suitable for Automatic baling machines and semi-automatic baling machines.

PLC control----PP strap making machine adopts PLC control system, which can save production parameters, simple debugging, stable operation, and clear data at a glance.

Winding machine---PP strap making machine can use automatic winding machine, automatic wiring, automatic roll change, automatic PE film wrapping, reduce labor and improve production efficiency

Winding machine---PP strap making machine can use automatic winding machine, automatic wiring, automatic roll change, automatic PE film wrapping, reduce labor and improve production efficiency

FAQ:

Q:What is the voltage of PP strapping equipment?

A:380V/50HZ, we support customization

Q:What is the length of the PP strapping belt?

A: L:36 M.

Q:Where is the PP strapping equipment produced?

A:We are from China.

Q:Can PP strapping equipment provide after-sales service?

A:Yes, we have professional after-sales engineers who provide 24-hour online guidance.

Q:Is the quality of PP strapping equipment stable?

A:We have 30 years of manufacturing experience, and have their own PP packaging belt production plant, equipment quality is stable, the process is worth choosing.

Q:Does PP strapping equipment support customization?

A:We are a manufacturing plant that can customize model size, extrusion capacity, voltage and so on according to customer requirements.

Q:What does the wrapping machine part of the PP strapping equipment look like?

A:Equipped with automatic wrapping machine/semi-automatic wrapping machine.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!

Algemene Beoordeling

Ratingsnapshot

Het volgende is de verdeling van alle beoordelingenAlle recensies